Advantages of choosing SPECIALIST+ smart storages:

More efficient manufacturing operations

Smart storage systems enhance manufacturing efficiency by automating inventory control, reducing downtime, and maximizing production floor space.

Stable production processes due to no lack of tools

The systems ensure stable production processes by guaranteeing tools and materials are always available, minimizing downtime and enhancing workflow continuity.

Inventory tracking and usage monitoring

Precise inventory tracking and usage monitoring ensures materials are consistently available and operations run smoothly.

Short and simple autonomised restocking

Smart storage systems maintain stable production with quick, automated restocking, ensuring essential selected supplies are always on hand.

How it works?

Customer indentificaiton

The customer (worker) is identified by a special card or individual password.

Pick-up of products

The required quantity of components is taken and the door is closed. The system counts the balances and allocates to the employee the quantity of components he has taken.

Automatic restocking

When the quantity of components reaches a set minimum balance threshold, the system generates an automatic order for the required components.

Statistical data analysis

The system allows real-time monitoring of balances, their usage, trend statistics or analysis

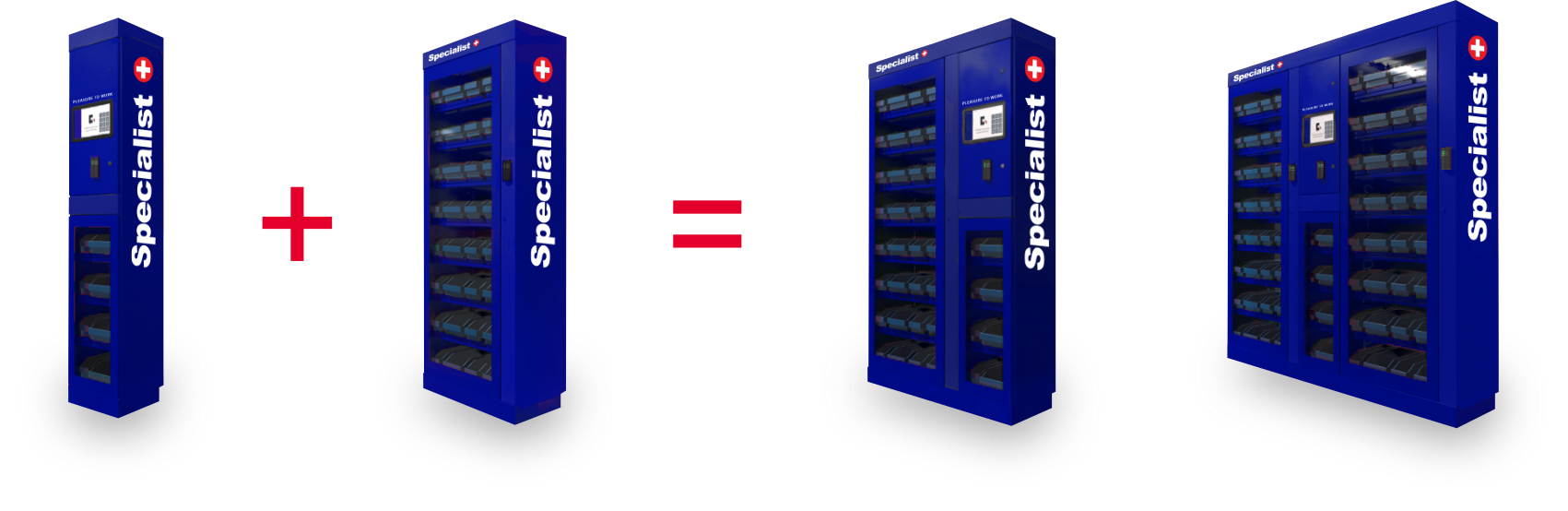

Equipment to suit your needs

Free of charge

0 €

/ month- Minimum turnover of 1500 EUR/month required.

- Product tracing

- Zero investment

- On-time and on-site product delivery by our sales representative

For businesses

from 2 €

/ month per 1 storage shelf- Supplies are only delivered via RM Tools, UAB. Available supply of goods out of our range at the best market price.

- Product tracing

- Zero investment

- On-time and on-site product delivery by our sales representative

For organisations

from 8000 €

VAT excl.- Full system control

- Product tracing

- Unlimited customization

- IT support

Automated stock control

Automatic stock-taking makes it easy to keep track of balances and order refills on time.

Integrated info display

Integrated touch screen for easy and quick worker identification and product display.

Warranty and maintenance

Fast and reliable warranty service and regular maintenance.

Individual inventory set-up

Easy replacement of components needed for the job, inventory replenishment according to company needs.

Easy to apply in manufacturing facilities

Easily adaptable to production facilities, especially those working within the LEAN framework.

Remotely monitored stocks

Remote monitoring, data analysis and management of existing stock of items.

Any questions? Get in touch with us

Let's discuss and find the best possible offer.